Introduction to Cabinet Screws

Cabinet screws, a vital component in woodworking, particularly in cabinet construction and installation, provide the structural integrity necessary for ensuring that cabinets function effectively and stand the test of time. These screws are specifically designed to penetrate wood and are commonly made from materials such as steel or stainless steel, which contribute to their strength and durability. The choice of cabinet screws greatly affects the overall strength and stability of the furniture, making the selection of the appropriate size paramount.

In the realm of furniture making, cabinet screws serve various applications. They are used to securely fasten cabinet faces to the frames, as well as to attach shelves, doors, and drawers. The design of a cabinet often dictates the specific type of screws required. For instance, frameless cabinets typically use different screw sizes compared to face-framed cabinets. Additionally, cabinet screws are often designed with a specific thread type, head style, and length, all of which play critical roles in the overall performance of the cabinetry.

Selecting the appropriate size cabinet screws is crucial for multiple reasons. A screw that is too short may not provide sufficient support, leading to instability and potential failure of the cabinet structure. Conversely, if the screw is too long, it could penetrate through the material and cause damage or compromise the aesthetics of the piece. It is also essential to consider the thickness of the material being joined, as this will further influence the correct size of cabinet screws. To that end, understanding what size cabinet screws to use not only promotes longevity but also enhances the overall craftsmanship and utility of the finished product.

Understanding Screw Dimensions

When selecting the appropriate screws for cabinetry, an understanding of screw dimensions is crucial. The key dimensions to consider are head size, shaft length, and diameter, all of which significantly affect the overall performance of the screw in various materials used in cabinet building.

Head size refers to the diameter of the screw’s top and plays an essential role in determining how well the screw will hold the materials together. A larger head offers a broader surface area, distributing weight and pressure more evenly. This can be particularly beneficial when working with softer woods that might be prone to stripping if a smaller head is used. Additionally, various head types, such as countersunk or flat, can provide specific aesthetic advantages in cabinetry, enhancing the overall finish while ensuring strength and stability.

The shaft length is another critical dimension to keep in mind while answering the question, what size cabinet screws should be chosen. This length dictates how deep the screw penetrates the materials it binds. If the shaft is too short, it may lead to inadequate fastening, compromising the integrity of the assembled furniture. Conversely, a shaft that is excessively long can lead to splitting or other damage to the materials being joined. It is, therefore, essential to choose a shaft length that corresponds to the thickness of the materials involved without risking damage.

Diameter, the thickness of the screw, can also influence its capability to bear weight and tension. A thicker diameter generally offers greater strength, which can be beneficial in applications requiring robustness, such as corners and joints in cabinets. However, it is also important to consider the materials being used; using a screw that is too thick for softer woods may lead to splitting. Taking into account head size, shaft length, and diameter is crucial to ensure the right cabinet screws are selected for optimal performance and durability.

Types of Cabinet Screws

When embarking on a cabinet installation project, selecting the right type of screw is paramount to ensuring both structural integrity and aesthetic appeal. Cabinet screws can be broadly categorized into three main types: wood screws, machine screws, and self-tapping screws. Each type serves distinct purposes and carries its own set of advantages and disadvantages.

Wood screws are the most commonly used cabinet screws due to their versatility. Designed with a sharp point and coarse threads, they are optimal for joining wooden materials. Their ability to grip the wood fibers makes them ideal for cabinetry installation, particularly when securing cabinet doors or shelving. However, over-tightening wood screws can lead to splitting the wood, which is a notable disadvantage. Moreover, they may not provide the same level of strength when used in composite or engineered wood products.

On the other hand, machine screws are typically employed in more robust applications. They are used in combination with nuts, washers, or threaded inserts, making them ideal for metal or heavy-duty woodworking applications. Their uniform diameter and threading allow for a secure fit, which is particularly advantageous for assembling modular cabinets. Nevertheless, machine screws generally require pre-drilled holes, adding an extra step to the installation process.

Self-tapping screws are another option that deserves consideration, especially for quick installations. These screws are designed to tap their own hole in materials such as metal or plastic, reducing the need for pre-drilling. They save time and effort in the assembly process, but their effectiveness is often contingent on the material’s thickness and density. While they offer convenience and rapid installation, their holding power may not match that of wood or machine screws in high-stress applications.

In conclusion, assessing the specific requirements of your cabinet project will guide you in choosing the appropriate type of screw. Understanding the uses, advantages, and limitations of wood screws, machine screws, and self-tapping screws is essential for a successful and durable cabinet installation.

Factors to Consider When Choosing Screw Size

When selecting the appropriate size cabinet screws, several critical factors must be taken into account to ensure the structural integrity and longevity of the installation. One of the primary considerations is the thickness of the cabinet material. Different materials, such as plywood, MDF, or particleboard, have varying thicknesses and densities, which influence the length and diameter of the screws required. Typically, screws should penetrate at least half the thickness of the material to ensure a secure fit. Thus, knowing the material’s specifications is essential for making an informed choice.

Another crucial factor to consider is the type of joint used in assembling the cabinet. For instance, a butt joint may require different screw sizes compared to a dovetail joint. The design of the joint affects how the forces are distributed across the assembled pieces, necessitating a screw size that can adequately support these forces. Additionally, the placement of screws within the joint is as critical as their size, as poorly placed screws may lead to weak points in the structure.

The weight of the items that the cabinet will hold is also vital in determining the right cabinet screws. Heavier loads require thicker and longer screws to prevent failure under weight stress. If the cabinet is intended to support substantial items, it would be prudent to use a screw that can accommodate these demands without compromising on structural stability.

Lastly, environmental conditions play a significant role in screw selection. Factors such as humidity, exposure to moisture, and temperature fluctuations can affect the type of screws you choose. For outdoor cabinets or areas with high humidity, stainless steel or coated screws are ideal due to their corrosion-resistant properties. By carefully evaluating these factors, one can determine the optimal size and type of cabinet screws necessary for a successful and durable installation.

Recommended Screw Sizes for Different Cabinets

Choosing the correct size cabinet screws is crucial for ensuring stability and longevity in any cabinetry project. The dimensions of screws you select can significantly affect the overall integrity of your cabinets. Below, we outline the standard screw sizes recommended for various types of cabinets, which include wall cabinets, base cabinets, and kitchen islands.

Wall Cabinets: For the mounting of wall cabinets, it is advisable to use 2.5-inch screws. These screws are designed to penetrate through the cabinet’s back support and into the wall stud, providing superior anchoring. If the wall cabinet is heavier or has additional shelves, consider using 3-inch screws for extra security.

Base Cabinets: Base cabinets typically require a different approach. It is recommended to use 2 to 2.5-inch screws for attaching the cabiner boxes to one another and securing them to the floor. These lengths ensure adequate support while minimizing the risk of protrusion through the bottom of the cabinet.

Kitchen Islands: For kitchen islands, the choice of screw size may depend on the size and weight of the countertop. Generally, 3-inch screws are suitable for securely fastening the island’s frame to the base, especially when using heavier materials. In some designs, additional screws may be necessary to connect the island to the cabinets and ensure stability.

It is essential to consider the material of the cabinets as well, as different woods or composite materials may require variations in screw size or type. Ultimately, selecting the appropriate size cabinet screws will contribute significantly to the structural integrity and overall quality of your cabinetry. When in doubt, always refer to the manufacturer’s recommendations or consult with a professional.

Tools and Techniques for Installing Cabinet Screws

When it comes to installing cabinet screws, having the right tools at your disposal can significantly impact the quality and efficiency of your work. Key tools include a power drill or screwdriver, a countersink bit, a tape measure, a level, and a square. A power drill is essential for both driving screws and pre-drilling holes, while a screwdriver may be preferable for more sensitive installations where precision is crucial.

To ensure the correct size cabinet screws are utilized, a tape measure is vital for measuring the thickness of the cabinet material. In conjunction with this, a square will help maintain right angles, ensuring that cabinets are installed squarely. Additionally, using a level during the installation process helps to achieve a professional finish, preventing any misalignment that could lead to complications down the line.

One effective technique is pre-drilling holes for the cabinet screws, especially in hardwood materials which can split easily. This is where a countersink bit comes into play; it creates a conical hole that allows the head of the screw to sit flush with the surface, enhancing aesthetic appeal and functionality. Pre-drilling also reduces the likelihood of the wood splitting while driving in the screws.

Proper alignment during installation is another crucial practice. As you secure the cabinet screws, ensure that they are inserted straight into the pre-drilled holes to avoid misalignment and to maximize structural integrity. Consider using clamps to hold pieces in place while performing the installation, providing added stability. Additionally, using a torque setting on your power drill ensures that screws are not overtightened, which can damage the materials associated with the cabinet.

By employing these tools and techniques, you can achieve a successful installation of cabinet screws, contributing to durable and well-fitted cabinetry in your home or project.

Common Mistakes to Avoid When Choosing Screw Sizes

Choosing the right size cabinet screws is essential for ensuring the stability and durability of any cabinetry installation. However, several common mistakes can undermine even the best-laid plans, leading to frustrating results. These pitfalls can affect both DIYers and professional carpenters alike.

One prevalent error is selecting screws that are too short for the application. When cabinet screws do not penetrate deeply enough into the supporting structure, such as a wall stud or the cabinet frame, they can compromise the integrity of the installation. Ensuring that the screw length is adequate is crucial; typically, screws should penetrate at least one inch into the supporting surface for optimal hold. Conversely, using excessively long screws can also be problematic, potentially damaging surrounding materials or protruding from the other side.

Another mistake is neglecting to consider the gauge or thickness of the screw. Using screws that are too thin may lead to a weaker connection, while screws that are too thick can cause splitting of the wood, especially if the material is soft or already pre-drilled. It is crucial to select a gauge that matches the load requirements and the material thickness of the cabinetry.

Additionally, many overlook the importance of screw material, especially in environments exposed to moisture. Choosing screws made from corrosion-resistant materials, such as stainless steel or coated options, is imperative for long-lasting durability. Finally, not conducting a thorough assessment of the cabinet’s weight and mounting structure can lead to miscalculations in screw size, resulting in insufficient support.

Avoiding these common mistakes when determining what size cabinet screws to use ensures a stable and successful installation, ultimately enhancing the longevity and functionality of your cabinetry.

Where to Buy Quality Cabinet Screws

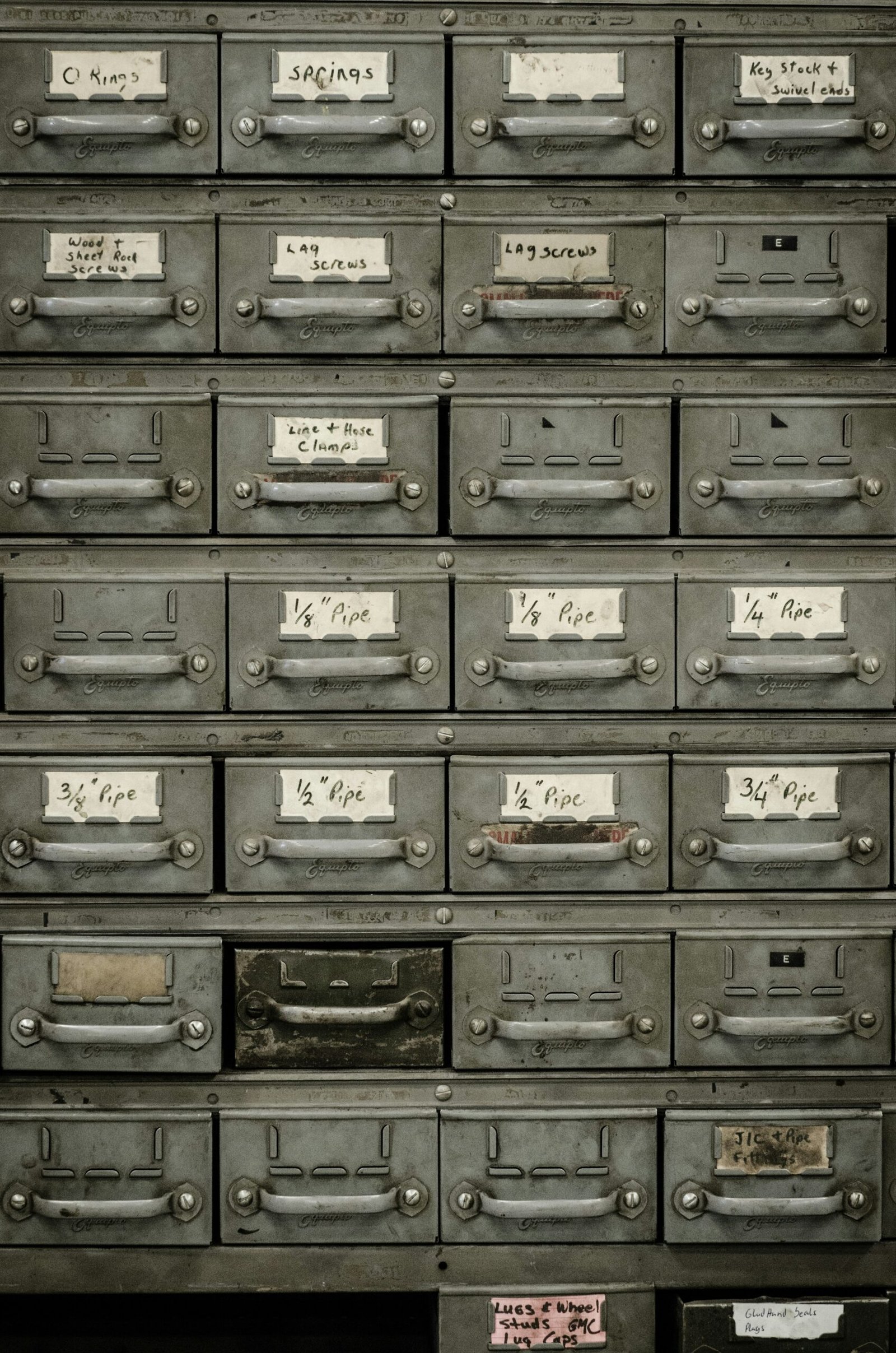

When it comes to purchasing cabinet screws, quality and reliability are paramount. The longevity and durability of cabinetry are significantly influenced by the type of screws used during assembly. Therefore, sourcing the right cabinet screws from reputable outlets is essential. There are various places where you can find high-quality cabinet screws that cater to a range of project needs.

Local hardware stores often provide a good selection of cabinet screws. These stores typically carry various sizes and styles, allowing you to evaluate options in person. Staff members at hardware stores can also offer valuable advice and recommendations based on experience. Additionally, since many hardware stores stock products suitable for specific applications, you may find screws that are perfectly suited for cabinetry.

Specialty woodworking shops also represent an excellent option for purchasing cabinet screws. These stores usually cater to the needs of both amateur and professional woodworkers, providing a more extensive range of products, including premium screws designed for cabinetry. In these shops, you can often find expert guidance and bespoke advice tailored to your project requirements, ensuring you select the right size cabinet screws for optimal results.

Online retailers have gained prominence for convenience and variety. Platforms like Amazon, Home Depot, and Lowe’s offer an extensive catalog of cabinet screws and allow for easy price comparison. Moreover, user reviews can provide insights into the quality and performance of the screws you are considering. Ensure that you look for sellers with a good reputation and check for warranties or guarantees when purchasing cabinet screws online.

In summary, whether you plan to purchase from a local hardware store, a specialty woodworking shop, or an online retailer, always prioritize quality in your selection of cabinet screws. The right size cabinet screws will not only enhance the assembly of your project but also ensure its long-term stability.

Conclusion: Making the Right Choice

Choosing the correct size cabinet screws is vital for a successful and long-lasting cabinet installation. The importance of selecting the right size cannot be overstated, as improperly sized screws can lead to structural weaknesses, unsightly gaps, and even costly repairs. Throughout this guide, we explored the various factors that influence the selection of cabinet screws, including the type of material being used, the specific application, and the overall design of the cabinetry.

As discussed, the size of the screws should complement the thickness of the materials involved and provide adequate holding power. For example, using screws that are too short may result in inadequate grip, while those that are overly long could damage the adjacent structures or materials. It is essential to understand the nuances of cabinet construction to determine what size cabinet screws will effectively secure the cabinetry without compromising its integrity.

Moreover, we highlighted different types of screws available in the market, such as wood screws and machine screws, each suited for various materials and applications. Understanding these options lays the foundation for making informed decisions when selecting cabinet screws. Remember that the diameter and length of the screws play a crucial role in their effectiveness, and it is advisable to follow manufacturer guidelines and best practices in the installation process.

Ultimately, the choice of what size cabinet screws to use should be aligned with the specific needs of your project. By carefully considering the details provided in this guide and applying the acquired knowledge, you can enhance the quality of your cabinet installations and ensure they meet your aesthetic and functional expectations. Making the right choice in terms of cabinet screws not only ensures durability but also contributes to achieving a professional finish.